Meeting Minutes Saturday June 9th, 2018

10:05-10:35 Alan Timm talked about his experience with the inexpensive laser cutter the K40 that sells for around $350 on ebay and other sites.

10:35-11:20 Carl Sutter talked about linear actuators from Servo City and motor controllers from Pololu

11:00-12:00 Thomas

12:00-12:35 Break - bring your snacks or lunch

12:35-12:45 Business Meeting

- Monthly Events

- Budget

- Next classes and Competitions

12:45- 1:15 Competition-

1:15 - 3:00 Show-N-Tell - Show us what you are working on! Open to anyone to show what they are working on or ask for opinions and getting possible solutions. Impress us with your best creation!

10:05-10:35 Alan Timm talked about his experience with the inexpensive laser cutter the K40 that sells for around $350 on ebay and other sites.

10:35-11:20 Carl Sutter talked about linear actuators from Servo City and motor controllers from Pololu

11:00-12:00 Thomas

12:00-12:35 Break - bring your snacks or lunch

12:35-12:45 Business Meeting

- Monthly Events

- Budget

- Next classes and Competitions

12:45- 1:15 Competition-

1:15 - 3:00 Show-N-Tell - Show us what you are working on! Open to anyone to show what they are working on or ask for opinions and getting possible solutions. Impress us with your best creation!

10:05-10:35 Alan Timm talked about his experience with the inexpensive laser cutter the K40 that sells for around $350 on ebay and other sites. Alan explained the upgrades he did to it, safety and software.

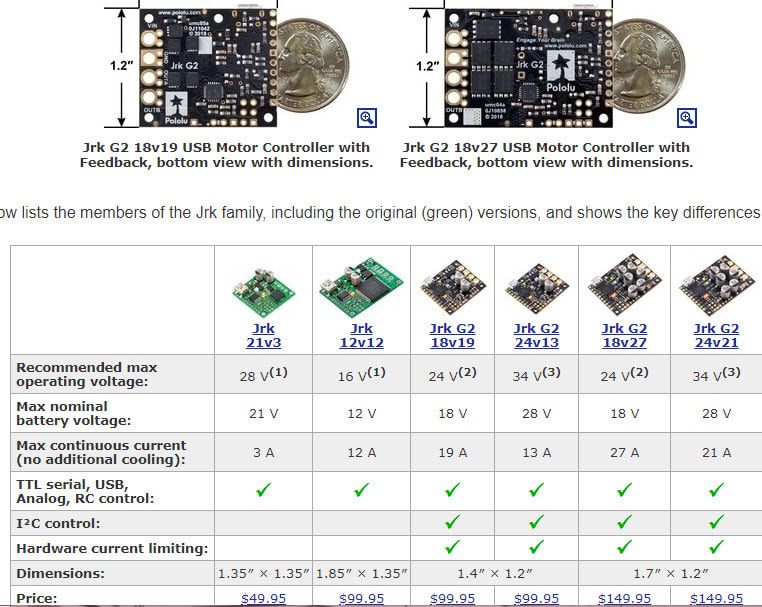

10:35-11:20 Carl Sutter from TeleToyland http://www.teletoyland.com/ talked about linear actuators from Servo City and motor controllers from Pololu

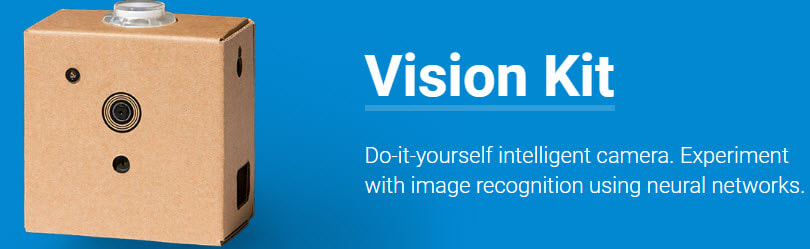

Carl also showed his Vision Kit from AIY Do it yourself artificial intelligence Projects This is a nice way to get started with AI, Tensor Flow, Vision ,etc.

Jim DiNunzio's code for the Voice Kit https://github.com/jimdinunzio/google-text-to-speech-demo

Jim DiNunzio's code for the Voice Kit https://github.com/jimdinunzio/google-text-to-speech-demo

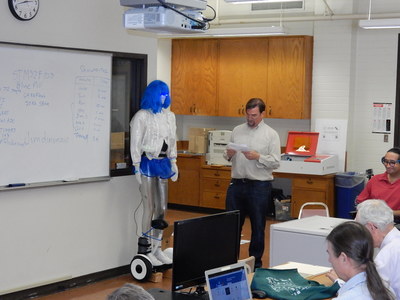

11:20 Walter Martinez demos the NAO robot responding to voice commands.

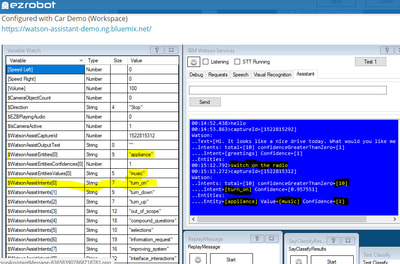

11:30-12:03 Thomas talked about his robot Betty 9, MS Cognitive Services and EZ-Robot interface to IBM Watson

|

|

|

12:30- Patricia Tsoiasue talked about the WRO competition WRO is the World Robot Olympiad yearly competition (only allowed to use Lego robots and specific competition mats and rules). It happens regionally then nationally and teams that win nationally go on to compete internationally.

Countries vary by year, topics vary by year. Is for elementary schools to high school and open projects ages up to 20+ years old. Rules are beautifully written: example of last year's http://www.wro2017.org/footballCategory.html and topics are relevant to today's world problems.

This time is in Thailand and the competition has 4 categories and they are assigned by age - elementary to high school and advanced max up to 25yrs old (for this one they allow Matrix/Tetrix kits and Legos plus LabView).

https://wro-association.org/competition/overview/

Last year's topic was on sustainability and energy. This year is on Food. The rules are below.

https://wro-association.org/wro-2018/games-rules/

What Patricia is proposing (this event is happening during our meeting time in August 2018 in the room next door to our meeting from 9am to ?):

- we will have the regional competition at CSULB on the day of our meeting as it was easier for us to get it approve by the Dean of the college of engineering (it is approved already). We did the same thing 2 years ago.

- we need volunteers such as judges and just provide support during the event (I've been a judge a couple of times and it very rewarding) you must learn the rules so study them carefully. Your scores are official and allows competitors to advance to nationals!.

- Patricia wants some financial sponsors to hire temp help and organizers. Most of us will be volunteering for this. It supports the world of robots and engineering for young participants and it makes a good name for our robotics society and the university that let's us meet there on a monthly basis.

We will need help creating some wooden platforms to mount the mats.

My last suggestion is that we already have the rules (even previous rules and mats), we will get the mats, why not use them for our society's monthly competitions? We can use any robots we build. They are challenging enough to keep us interested and they are fun to do. See sample competition video below.

Countries vary by year, topics vary by year. Is for elementary schools to high school and open projects ages up to 20+ years old. Rules are beautifully written: example of last year's http://www.wro2017.org/footballCategory.html and topics are relevant to today's world problems.

This time is in Thailand and the competition has 4 categories and they are assigned by age - elementary to high school and advanced max up to 25yrs old (for this one they allow Matrix/Tetrix kits and Legos plus LabView).

https://wro-association.org/competition/overview/

Last year's topic was on sustainability and energy. This year is on Food. The rules are below.

https://wro-association.org/wro-2018/games-rules/

What Patricia is proposing (this event is happening during our meeting time in August 2018 in the room next door to our meeting from 9am to ?):

- we will have the regional competition at CSULB on the day of our meeting as it was easier for us to get it approve by the Dean of the college of engineering (it is approved already). We did the same thing 2 years ago.

- we need volunteers such as judges and just provide support during the event (I've been a judge a couple of times and it very rewarding) you must learn the rules so study them carefully. Your scores are official and allows competitors to advance to nationals!.

- Patricia wants some financial sponsors to hire temp help and organizers. Most of us will be volunteering for this. It supports the world of robots and engineering for young participants and it makes a good name for our robotics society and the university that let's us meet there on a monthly basis.

We will need help creating some wooden platforms to mount the mats.

My last suggestion is that we already have the rules (even previous rules and mats), we will get the mats, why not use them for our society's monthly competitions? We can use any robots we build. They are challenging enough to keep us interested and they are fun to do. See sample competition video below.

|

|

|

1:09 Business Meeting

- Treasurer Ron Rose proposed we move our account to US Bank and it was approved. We will avoid paying any fees.

- Bill mentioned spend $50 at Arrow Electronics you get a free Raspberry Pi 3

- Bob Huss talked about the Clean The Room contest. More points if you identify a real soda can.

- Treasurer Ron Rose proposed we move our account to US Bank and it was approved. We will avoid paying any fees.

- Bill mentioned spend $50 at Arrow Electronics you get a free Raspberry Pi 3

- Bob Huss talked about the Clean The Room contest. More points if you identify a real soda can.

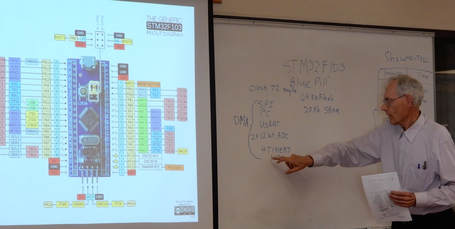

1:22 Ron Rose showed a new processor board STM32F103 and is asking for someone who can experiment with it. Looks like we can program it using the Arduino IDE. They cost less than $4 and can be purchased at Amazon for example.

Chris Albertson: One neat fact, the pins are 5 volt tolerant. So the board is a grop-in upgrade fro an Arduino UNO. It is quite a bit more powerful and and 1/4 the price.Yes you an use the USB cable if you first install an Arduino boot loader. One different from the uno is the the USB cable can not do a reset so you need to press the reset button to program it.

But there is a better why to use these. Arduino is very limiting ... Look up "mBed". It is a system like Arduino IDE but a big step up and better suited to the ARM. mBed has two ways to go, one is the on-line compiler and there is an offline version too. But for simple things the on0line one works best as there is nothing to install on your computer.

Then if you are writing code using mBad and you need a more powerful processor it scales. I'm using this STM32F103 bu also have some bigger ones that run at 180 MHz and have 2MB of Flash ROM.

With this board you WILL NEED an ST Link programmer to load the boot loader. There is no boot loader in when you buy them. At $2 each it is easy to find uses for these

But there is a better why to use these. Arduino is very limiting ... Look up "mBed". It is a system like Arduino IDE but a big step up and better suited to the ARM. mBed has two ways to go, one is the on-line compiler and there is an offline version too. But for simple things the on0line one works best as there is nothing to install on your computer.

Then if you are writing code using mBad and you need a more powerful processor it scales. I'm using this STM32F103 bu also have some bigger ones that run at 180 MHz and have 2MB of Flash ROM.

With this board you WILL NEED an ST Link programmer to load the boot loader. There is no boot loader in when you buy them. At $2 each it is easy to find uses for these

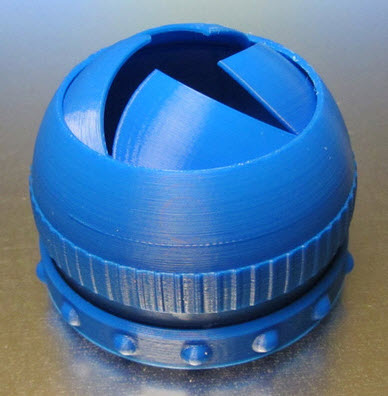

1:35 Ben Partisi showed us his successful print of the an Iris Boxhttps://www.thingiverse.com/thing:1817180

The slicer setting is used are:

Filament: ABS (but you can use PLA if you prefer)

Hot end temp: 210 C

Heat bed temp: 90 C

Layer height: .20 mm

Shell thickness

Normal (vertical wall): 3 layers

Top and bottom: 5 layers (you can play with this) since I printed it using ABS plastic I use a 5mm brim (to prevent warping)

The more crucial settings are your retraction settings, that is how much the extruder is going to pull back the filament when hot end jumps a gap. A bad extrusion rate will results in stringiness in your part where the hot end had to jump between two points in the part. For some other part that might just be a slight nuisance that you have to clean up but for this print that has such tight tolerances that will result in the part ending up completely welded solid.

The retraction settings will be different for every printer specially for RepRap printers so my settings will most likely not work for yours. This is something you have to play with to find the best settings for your printer.

Here is a link to a retraction testing print: https://www.thingiverse.com/thing:909901

The other critical setting is your extrusion multiplier. This is another setting that will be unique to your printer and the roll of filament you are using so my setting probably wont work for you. This setting changes how much plastic is actually extruded out the hot end. This is critical for a part like this because every roll of filament, even though, the box says its 1.75 mm or 3 mm filament the actual diameter WILL be different so you have to change the extrusion multiplier to fit the filament to the printer. When you find the correct rate for your filament/printer the parts will be pretty dimensionally close to the drawing.

Thats pretty much it, its a fun print.

You can take it further and do a Hawk Eye

The slicer setting is used are:

Filament: ABS (but you can use PLA if you prefer)

Hot end temp: 210 C

Heat bed temp: 90 C

Layer height: .20 mm

Shell thickness

Normal (vertical wall): 3 layers

Top and bottom: 5 layers (you can play with this) since I printed it using ABS plastic I use a 5mm brim (to prevent warping)

The more crucial settings are your retraction settings, that is how much the extruder is going to pull back the filament when hot end jumps a gap. A bad extrusion rate will results in stringiness in your part where the hot end had to jump between two points in the part. For some other part that might just be a slight nuisance that you have to clean up but for this print that has such tight tolerances that will result in the part ending up completely welded solid.

The retraction settings will be different for every printer specially for RepRap printers so my settings will most likely not work for yours. This is something you have to play with to find the best settings for your printer.

Here is a link to a retraction testing print: https://www.thingiverse.com/thing:909901

The other critical setting is your extrusion multiplier. This is another setting that will be unique to your printer and the roll of filament you are using so my setting probably wont work for you. This setting changes how much plastic is actually extruded out the hot end. This is critical for a part like this because every roll of filament, even though, the box says its 1.75 mm or 3 mm filament the actual diameter WILL be different so you have to change the extrusion multiplier to fit the filament to the printer. When you find the correct rate for your filament/printer the parts will be pretty dimensionally close to the drawing.

Thats pretty much it, its a fun print.

You can take it further and do a Hawk Eye

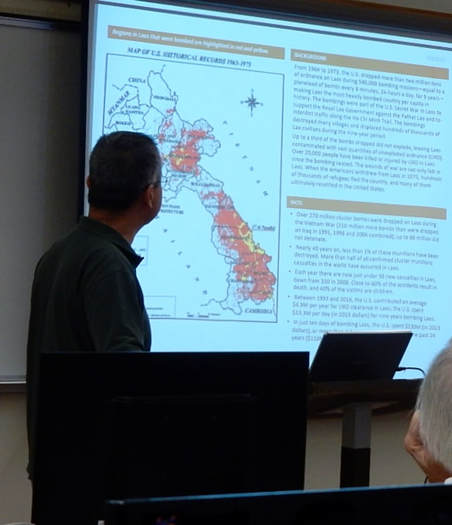

1:40 Sam is a new member is working on a project to help detect land mines in Laos. He is looking for someone who can design an off road vehicle that can carry the mine detection sensor. See https://www.uxolao.org/ fore more information. He would like to partner up with someone who is interested in working on this project with him. Contact RSSC for more info.

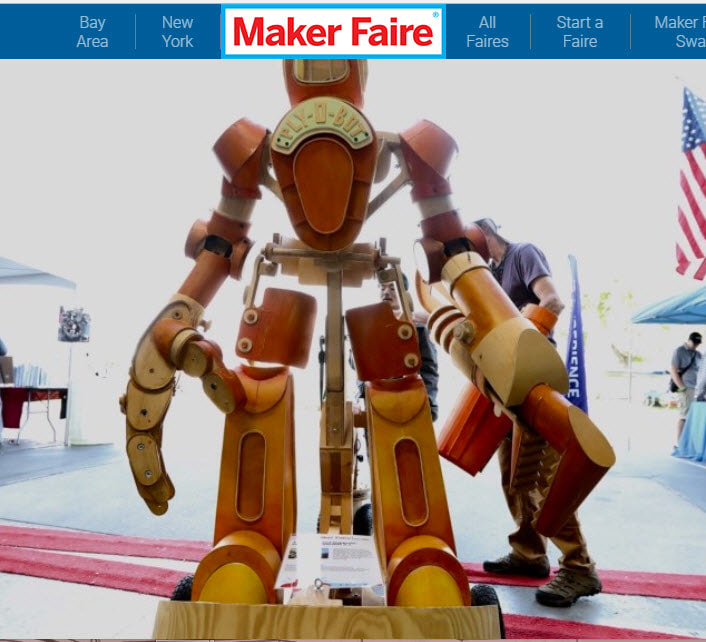

2:02 Jim DiNunzio showed us photos from his trip to the San Mateo 2018 Maker Faire

Check out Jim's personal photos here https://www.flickr.com/photos/jimdinunzio/sets/72157697602084715/

Check out Jim's personal photos here https://www.flickr.com/photos/jimdinunzio/sets/72157697602084715/

Jim DiNunzio: I've uploaded pictures and videos from Maker Faire Bay Area 2018 from San Mateo, CA from May 19-20th. Several have with captions with web addresses, etc. In order to see the captions start by clicking on the first picture and then use your right arrow key to advance. Internet Explorer seems work better at not cutting off the captions! Yes, after writing this I really want to find a better photo site than flickr!

https://flic.kr/s/aHsmmLEPgZ

It was a a really fun event to attend. They had a whole tent building for robotics exhibitors. A highlight for me was seeing the cool bots that the HomeBrew Robotics Club of Silicon Valley had on display. Anybody know them? I want to build the Lego NXT balancing robot.

The BB8 bot was pretty amazing. The woman we spoke with spent 2 years on the internals and a guy spent 6-8 months on his enclosure / exterior detail..

We met a guy with an InMoov build from Galileo U.. in Guatemala, Diego Calibron (I think), who has been in touch with Alan in the past for expert advice.

Josef Prusa on a fabrication panel there, and I got super support from the Prusa 3D booth on questions about my 3D-printer.

Massimo Banzi, co-founder of Arduino gave a presentation as well about their newest boards including a supposedly easy to use FPGA board called MKR Vidor 4000 that you can program with your own hardware design and is supported by plug and play Arduino libraries.

There was just so much going on I could only see a slice of it. I'm still going through Makezine's coverage of the event:

https://makezine.com/2018/05/18/live-updates-maker-faire-bay-area-2018/

https://flic.kr/s/aHsmmLEPgZ

It was a a really fun event to attend. They had a whole tent building for robotics exhibitors. A highlight for me was seeing the cool bots that the HomeBrew Robotics Club of Silicon Valley had on display. Anybody know them? I want to build the Lego NXT balancing robot.

The BB8 bot was pretty amazing. The woman we spoke with spent 2 years on the internals and a guy spent 6-8 months on his enclosure / exterior detail..

We met a guy with an InMoov build from Galileo U.. in Guatemala, Diego Calibron (I think), who has been in touch with Alan in the past for expert advice.

Josef Prusa on a fabrication panel there, and I got super support from the Prusa 3D booth on questions about my 3D-printer.

Massimo Banzi, co-founder of Arduino gave a presentation as well about their newest boards including a supposedly easy to use FPGA board called MKR Vidor 4000 that you can program with your own hardware design and is supported by plug and play Arduino libraries.

There was just so much going on I could only see a slice of it. I'm still going through Makezine's coverage of the event:

https://makezine.com/2018/05/18/live-updates-maker-faire-bay-area-2018/

2:29 Thomas demoed with Bettie 9 using Amazon Blueprints to answer preset questions and answers. You can visit Thoma's YouTube Channel https://www.youtube.com/user/thomasfromriverside